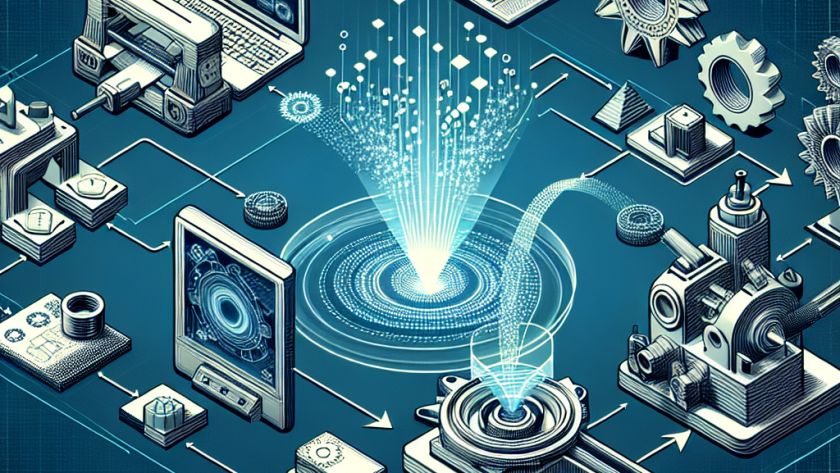

Photolithography is a commonly used manufacturing process that manipulates light to etch features onto surfaces, creating computer chips and optical devices like lenses. However, minute deviations in the process often result in these devices not matching their original designs. To bridge this design-manufacturing gap, a team from MIT and the Chinese University of Hong Kong…